- Présentation de l'entreprise Le noyau de Shanghai Metal Vision & philosophie Partenariat Certificat Culture d'entreprise

- Nos services Conception et ingénierie Maintenance et entretien Fabricant & Fabrication Mise à jour et transformation Stockage et logistique Traitement et commerce

- Gestion d'entrepise Notre histoire Responsabilité globale

- Centre d'achat Stagiarie

- Produit métallique Produits en aluminium Produits en cuivre Produits revêtus métalliques Produits en acier inoxydable Produits en acier carboné Alliages spéciaux

- Construction & Projet Caillebotis en acier Étagère Structure en acier Pont en acier Système d'échafaudage Matériaux de construction Matériel Chimique One-Stop Solutions pour les Projects

- Conteneur Conteneur standard ISO Conteneur d'équipement Conteneur de stockage Maison conteneur Conteneur frigorifique / isolé Conteneur offshore

- Machine Machine à former des métaux Autres machines Machine à découper les métaux Machine de traitement des métaux Machine à cintrer Machine d'aggloméré

- Produits mécaniques Industrie automobile Divers Équipement d'amarrage Equipment marin Récipient à pression

- Système électromécanique Câble Automation Distribution d'énergie Système d'alimentation solaire Système de protection électrique Convertisseur Ligne de production Système d'éclairage

- Matériel médical Produits de nourriture Produits de voies aériennes Produits de soins infirmiers Produits d'injection

- Machines de construction

- projet epc

- Tuyaux de pétrole

- Tuyaux de l'eau

- Tuyau de gaz

- Bateau et accessoires d'amarrage

- Produit métallique pour la décoration

- Composant du transformateur

- Pipe d'échangeur de chaleur

- Pièces et accessoires de climatisation

- Chaudière

- Appareil de cuisine et de salle de bains

- Métal pour appareils ménagers

- Appareil solaire

- Ascenseur

- Toiture et plafond

- Câble

- Tank

- Emballage

- Pièces détachées et accessoires pour machines et équipements

- Moule

- Pièces d'automobile

- Rail et rail de grue

- Équipement de quincaillerie

- abrasif

- Construction de route

- Composants electroniques

- Matériaux de construction et de décoration

- Portes et fenêtres

- Réfrigérateurs

- News release Nouvelles de l'industrie métallurgique Nouvelles de la machinerie et de l'équipement Nouvelles de la construction et du bâtiment Nouvelles des produits mécaniques Nouvelles de conteneurs Nouvelles du système électrique Nouvelles des matériels médicaux

- Médiathèque Vidéo Image Suivez Shanghai Metal sur les médias sociaux

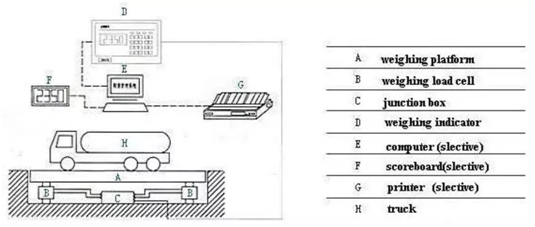

Electronic Truck Scale Management System

Width: 2~3.5m

length: 6m, 7m, 8m, 9m, 10m, 12m, 14m, 16m, 17.4m, 18m, 21m, 24m

Capacity: 10~200ton

A Truck scale (US), weighbridge (non-US) or railroad scale is a large set of scales, usually mounted permanently on a concrete foundation, that is used to weigh entire rail or road vehicles and their contents.

By weighing the vehicle both empty and when loaded, the load carried by the vehicle can be calculated.

2.1 Trunk Scale

It refers to a mechanical platform that transfers the weight of an object to a weighing sensor (load cell).

Here are the usual platform dimensions:

|

Type |

CSC-10 |

CSC-15 |

CSC-20 |

CSC-30 |

CSC-50 |

CSC-60 |

CSC-80 |

CSC-100 |

CSC-120 |

CSC-150 |

CSC-200 |

|

Platform dimension: W x L(m) |

|||||||||||

|

5 X 2 |

♣ |

♣ |

|

|

|

|

|

|

|

|

|

|

6 X 2.2 |

♣ |

♣ |

♣ |

|

|

|

|

|

|

|

|

|

6 X 2.4 |

|

♣ |

♣ |

|

|

|

|

|

|

|

|

|

6 X 2.5 |

|

♣ |

♣ |

♣ |

|

|

|

|

|

|

|

|

7 X 2.5 |

|

|

♣ |

♣ |

|

|

|

|

|

|

|

|

7 X 3 |

|

|

|

♣ |

♣ |

♣ |

♣ |

|

|

|

|

|

8 X 3 |

|

|

|

♣ |

♣ |

♣ |

♣ |

♣ |

|

|

|

|

9 X 3 |

|

|

|

♣ |

♣ |

♣ |

♣ |

♣ |

|

|

|

|

10 X 3 |

|

|

|

♣ |

♣ |

♣ |

♣ |

♣ |

|

|

|

|

12 X 3 |

|

|

|

♣ |

♣ |

♣ |

♣ |

♣ |

♣ |

♣ |

|

|

14 X 3 |

|

|

|

♣ |

♣ |

♣ |

♣ |

♣ |

♣ |

♣ |

|

|

15 X 3 |

|

|

|

♣ |

♣ |

♣ |

♣ |

♣ |

♣ |

♣ |

|

|

16 X 3 |

|

|

|

♣ |

♣ |

♣ |

♣ |

♣ |

♣ |

♣ |

|

|

16 X 3.3 |

|

|

|

|

|

|

♣ |

♣ |

♣ |

♣ |

|

|

16 X 3.5 |

|

|

|

|

|

|

♣ |

♣ |

♣ |

♣ |

|

|

18 X 3 |

|

|

|

|

|

|

♣ |

♣ |

♣ |

♣ |

♣ |

|

18 X 3.3 |

|

|

|

|

|

|

♣ |

♣ |

|||

Technical information of Electronic Truck Scale Management System:

Truck Scale basic specification:

|

Platform Width |

2~3.5m |

|

Platform Length |

6~24m |

|

Platform Thickness |

8-12mm thick tread plate |

|

Weighing Capacity |

10~200ton |

|

Structure |

U-shape beams |

|

Painting |

Anti-rust and anti-corrosion painting |

|

Accuracy class |

OIML III |

|

Safe Overload |

150% rated capacity |

|

Working temperature(Scale body) |

-30℃~+70℃ |

|

Working temperature(Indicator) |

-10℃~+40℃ |

|

Standard Accessories |

Load cell, Indicators, junction box, Signal cable and other standard equipment (e.g. lightning protector) |

|

Operating power supply |

240 / 220 / 110VAC, 50 / 60Hz |

*Load Cell is the core component of the truck scale, which plays the role of converting the weight value into the corresponding measurable electric signal. Its advantages and disadvantages are directly related to the quality of the whole Truck Scale.

Load Cell specifications:

|

Accuracy Class |

|

OIML III |

||

|

Output Sensitivity(=FS) |

mV/V |

2.0±0.002 |

||

|

Rated Capacity(Emax) |

T |

10/20/25 |

30/40LE/40/50 |

|

|

Maximum Number of Load Cell Intervals(nLC) |

|

3000 |

||

|

Ratio of Minimum LC Verification Interval Y=Emax/Vmin |

|

15000 |

7500 |

|

|

Combined error |

% F.S |

±0.023 |

||

|

Minimum Dead Load |

klb |

0 |

||

|

Safe Overload |

%F.S |

150 |

||

|

Destructive Load |

%F.S |

300 |

||

|

Zero Balance |

%F.S |

±1.5 |

||

|

Excitation Recommended |

V |

4~12(DC), Max:18(DC) |

||

|

Input Resistance |

Ω |

700±7 |

||

|

Output Resistance |

Ω |

700±7 |

||

|

Insulation Resistance |

MΩ |

≥5000(50VDC) |

||

|

Compensated Temperature |

°C |

-10~+40 |

||

|

Operating Temperature |

°C |

-35~+65 |

||

|

Storage Temperature |

°C |

-40~+70 |

||

|

Cable |

|

|||

Packaging of Electronic Truck Scale Management System:

In one 40’ container, we can load 2 units of 18m trunk scale or 2 units of the one less long than 18m

Truck scales can be used for two main purposes:

Selling or charging by weight over the bridge (Trade Approved)

Check weighing both axle weights and gross vehicle weights. This helps to stop axle overloading and possible heavy fines.

They are used in industries that manufacture or move bulk items, such as in mines or quarries, garbage dumps / recycling centers, bulk liquid and powder movement, household goods, and electrical equipment. Since the weight of the vehicle carrying the goods is known (and can be ascertained quickly if it is not known by the simple expedient of weighing the empty vehicle) they are a quick and easy way to measure the flow of bulk goods in and out of different locations.

A single axle truck scale or axle weighing system can be used to check individual axle weights and gross vehicle weights to determine whether the vehicle is safe to travel on the public highway without being stopped and fined by the authorities for being overloaded. Similar to the full size truck scale these systems can be pit mounted with the weighing surface flush to the level of the roadway or surface mounted.

For many uses (such as at police over the road truck weigh stations or temporary road intercepts) weighbridges have been largely supplanted by simple and thin electronic weigh cells, over which a vehicle is slowly driven. A computer records the output of the cell and accumulates the total vehicle weight. By weighing the force of each axle it can be assured that the vehicle is within statutory limits, which typically will impose a total vehicle weight, a maximum weight within an axle span limit and an individual axle limit. The former two limits ensure the safety of bridges while the latter protects the road surface.

ici

pour

prix

We will contact with you within 8 hours