- Présentation de l'entreprise Le noyau de Shanghai Metal Vision & philosophie Partenariat Certificat Culture d'entreprise

- Nos services Conception et ingénierie Maintenance et entretien Fabricant & Fabrication Mise à jour et transformation Stockage et logistique Traitement et commerce

- Gestion d'entrepise Notre histoire Responsabilité globale

- Centre d'achat Stagiarie

- Produit métallique Produits en aluminium Produits en cuivre Produits revêtus métalliques Produits en acier inoxydable Produits en acier carboné Alliages spéciaux

- Construction & Projet Caillebotis en acier Étagère Structure en acier Pont en acier Système d'échafaudage Matériaux de construction Matériel Chimique One-Stop Solutions pour les Projects

- Conteneur Conteneur standard ISO Conteneur d'équipement Conteneur de stockage Maison conteneur Conteneur frigorifique / isolé Conteneur offshore

- Machine Machine à former des métaux Autres machines Machine à découper les métaux Machine de traitement des métaux Machine à cintrer Machine d'aggloméré

- Produits mécaniques Industrie automobile Divers Équipement d'amarrage Equipment marin Récipient à pression

- Système électromécanique Câble Automation Distribution d'énergie Système d'alimentation solaire Système de protection électrique Convertisseur Ligne de production Système d'éclairage

- Matériel médical Produits de nourriture Produits de voies aériennes Produits de soins infirmiers Produits d'injection

- Machines de construction

- projet epc

- Tuyaux de pétrole

- Tuyaux de l'eau

- Tuyau de gaz

- Bateau et accessoires d'amarrage

- Produit métallique pour la décoration

- Composant du transformateur

- Pipe d'échangeur de chaleur

- Pièces et accessoires de climatisation

- Chaudière

- Appareil de cuisine et de salle de bains

- Métal pour appareils ménagers

- Appareil solaire

- Ascenseur

- Toiture et plafond

- Câble

- Tank

- Emballage

- Pièces détachées et accessoires pour machines et équipements

- Moule

- Pièces d'automobile

- Rail et rail de grue

- Équipement de quincaillerie

- abrasif

- Construction de route

- Composants electroniques

- Matériaux de construction et de décoration

- Portes et fenêtres

- Réfrigérateurs

- News release Nouvelles de l'industrie métallurgique Nouvelles de la machinerie et de l'équipement Nouvelles de la construction et du bâtiment Nouvelles des produits mécaniques Nouvelles de conteneurs Nouvelles du système électrique Nouvelles des matériels médicaux

- Médiathèque Vidéo Image Suivez Shanghai Metal sur les médias sociaux

Machine à plier les tubes

Max. bending angel: 190°

Max. bending radius: 800 mm

Control system: Microcomputer Control & NC Control

Machine à cintrer hydraulique à tête unique:

Caractéristiques:

1. approprié pour plier le tuyau de grand diamètre, l'angle de 0 ° à 180 ° peut être ajusté aléatoirement.

2. la technologie peut fournir tous les types de pipe, la spécification moins de 8 ″ est complétée

3. adopte le circuit d'intégration hydraulique parallèle, le contrôle de mouvement est individuel, de sorte que les composants hydrauliques aient une longue vie.

4. le circuit à trois sections, avec la fonction de refroidissement, et peut même faire l'huile hydraulique ne produit pas la dégénérescence

5. axe par raffinage thermique, main de pliage forgée par l'acier spécial, pièces par inspection rigoureuse de qualité, qualité supérieure, spécification unifiée

6. il a la fonction de manuel et automatique simultanément, et a enfermé le dispositif d'arrêt d'urgence.

7. peuvent être réglés divers angles et mutuellement prennent des virages fléchissant, ainsi évitent la difficulté du transfert.

8. la machine d'accueil est commandée par l'équipement électrique, bien que le travailleur non qualifié puisse joindre promptement la procession de produit aussi.

9. peut équiper la longueur automatique d'alimentation, placer l'angle, finir la pipe compliquée et épargner le coût de main-d'oeuvre.

10. longueur d'alimentation automatique et segment d'alimentation, et définissez la variété de l'angle, selon les besoins du consommateur et les productions.

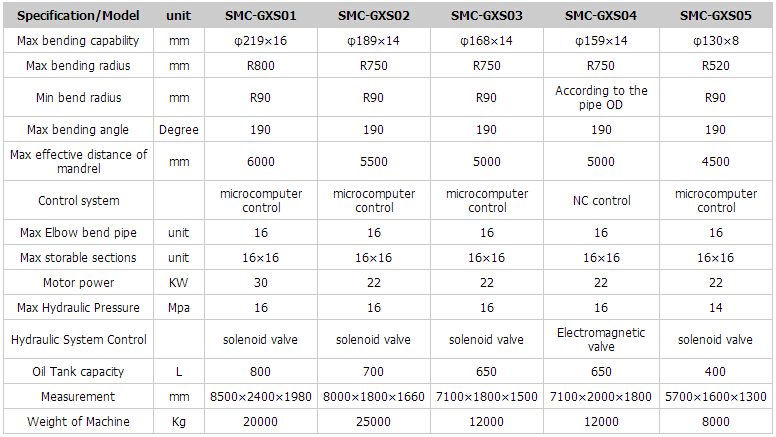

Modèles:

SMC-GS01, SMC-GS02, SMC-GS03, SMC-GS04, SMC-GS05,SMC-GS06, SMC-GS07, SMC-GS08, SMC-GS09, SMC-GS10, SMC-GS11, SMC-GS12,etc

Double machine hydraulique de pliage de pipe:

Caractéristiques:

1. machines à haute vitesse à double tuyau

2. l'utilisation du contrôle NC rend votre opération et la programmation est plus un Compendium.

3. approprié à l'automobile, siège, assurance de motocyclette, bar et bureau, meubles de salle à manger et décoration extérieure.

Modèles:

SMC-GD01, SMC-GD02, SMC-GD03, SM-SW38

Single-head Hydraulic Pipe Bending Machine:

Features:

1. Suitable for bending large diameter pipe, the angle from 0°to 180°can be adjusted randomly.

2. Technology can provide all types of pipe, the specification less than 8″is completed

3. Adopts hydraulic parallel integrate circuit, movement control is individual, so that the hydraulic components have a long life.

4. Three-section circuit, with cooling function, and even can make the hydraulic oil does not produce degeneration

5. spindle by thermal refining, bending hand forged by special steel, parts by stringent quality inspection, superior quality, unified specification

6. It has the function of both manual and automatic concurrently, and enclosed the emergency stop device.

7. Can be set various angles and mutual take turns bending, so avoid the trouble of transfer.

8. Host machine is controlled by electric equipment, even though unskilled worker can join the produce procession promptly, too.

9. Can equip automatic feeding length, set angle, finish complicated pipe and save manpower cost.

10. Automatic feeding length and feeding segment, and set variety of angle, according to consumer’s needs and productions.

Models:

SMC-GS01, SMC-GS02, SMC-GS03, SMC-GS04, SMC-GS05,SMC-GS06, SMC-GS07, SMC-GS08, SMC-GS09, SMC-GS10, SMC-GS11, SMC-GS12,etc

Double Hydraulic Pipe Bending Machine:

Features:

1. Double pipe high-speed machines

2. The use of NC control makes your operation and programming is more a compendium.

3. Suitable for automotive, seat, motorcycle insurance, bar and office, dining furniture and outdoor decoration.

Models:

SMC-GD01, SMC-GD02, SMC-GD03, SM-SW38

CNC Pipe Bending Machine:

Brief introduction:

Machine is PLC control、hydraulic to drive, touch screen operation system, It is of man-machine dialogue-type operation, with simple setting and input. Hand-operated or automatic mode can be randomly selected and be automatically changed over. The Movable foot switch is of two kinds of function, i.e. starting, crash stop. Multiple pipes with small diameter can be bent and formed once. Hydraulic system、control system、drove system、display system etc adopts import parts, high accuracy、high efficient、It’s suitable for mass production,The machine we produced is in advanced level home and abroad. It’s CNC fully automatic machine which is suitable for bending 3D pipe sample, Just need to input program, the machine can finish the sample automatically. This machine is easy operation、stable property、high efficiency、safety and other strong point. It’s perfect machine for pipe processing.

Hardware:

1. Computer using level above than Inter Pentium 42.×G or AMD XP2xxxG

2. Five slots with high-speed PCI interface

3. 256M CCP RAM high-speed large-capacity memory×1

4. High-speed AGP 64M 3D accelerated display adapter×1

5. 40G removable hard drive×2

6. 1.44 floppy drive×1

7. 10/100 high-speed network interface

8. USB1.1/2.0 high-speed communication interface×6

9. 52×high-speed CD-ROM driver×1

10.4-axis (8 axes) PIC high speed control card Xx

11.96 point configurable PCI high-speed DI/O control card×1

12.485 communication module +D/A control module×1

CNC Type function

System function:

1. The function of X.Y.Z and Y.B.C mutual convert.

2. The set of flexible tube processing, can set feed/back bend/ corner function after the displacement come out or in, to avoid interference point, and can set the corner, where the number of layers, to avoid the interference caused by transferred tube.

3. The time of come in clamp change to draw back clamp can be set, First shape to tube, to prevent tube rebound.

4. When open old file, can preview the 3D pipe fitting model and related mold information in time, and file storage category, find information quickly and easily.

5. Multi-axis servo motion, fine-tuning can be set 99 speeds

6. Screen and password protection function, to prevent outsiders changes without permission, resulting in abnormal.

7. 5 kinds of simultaneous dynamic processes speed up the operating speed and avoid the problem of motion interference.

8. Manual servo controls, can set the absolute and relative location of exercise accurately and fast

9.Parameters of Single-bend tube workpiece set archive independently, so they don’t turbid and conflict with multi-curved tube information.

10. Y.B.C data input designed, can display 3D tube model immediately. On one side the data entry and the other side it shows the correct 3D tube model immediately, which can find out the error and amend it at once.

11. Semi/full automatic bend can show 3D tube model and simulated bend immediately.

12. Have the function of pipe work counting and count backwards.

13.The function of guided-mode repeated sends can set the degree of actions, to match with wide-angle curved tube.

14. The function of feed auxiliary push, aiding bend pipe reduce extended deformation.

15. Catheter displacement movement can be set out or in, to prevent scratches tube surface

16. Can set pipe or non-pipe (square pipe) bending function.

17. Can set the time of withdraw clamp A, avoid interference.

18. Can set into the corner, delay the time of withdraw clamp, auxiliary tube shape, reducing the tube problem of bounce.

19. Can set foot 0/1/2 times, coordinate with take tube movement; speed up the tube process degree.

20. Can display the completion time of each tube and pipe information under the automatic circumstance.

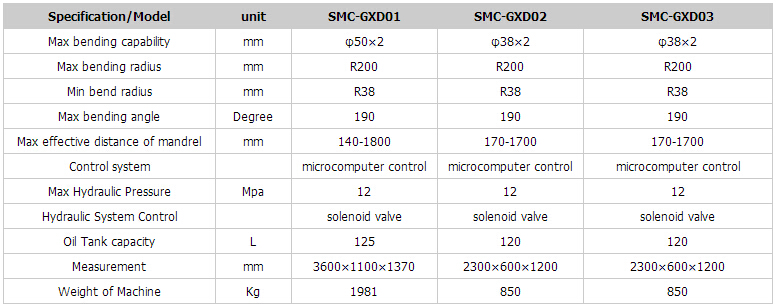

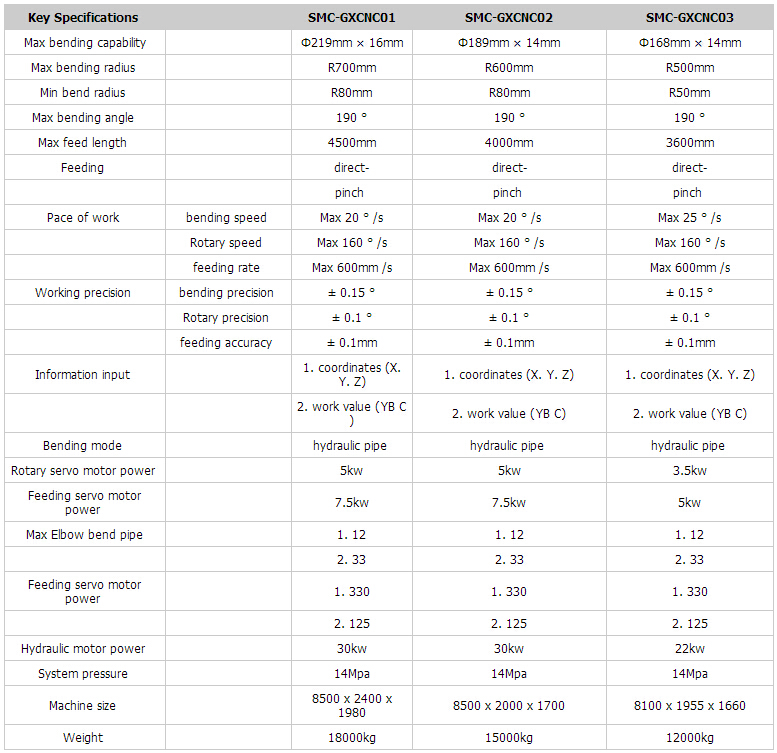

Models:

SMC-GCNC01, SMC-GCNC02, SMC-GCNC03, etc

Applications of Pipes and tubes:

1. Agriculture/Automotive

2. Buildings

3. Furniture

4. Ornamental

5. Windows/Doors

6. General

7. Agriculture/Automotive

8. Buildings

9. Furniture

10. Ornamental

11. Windows/Doors

ici

pour

prix

We will contact with you within 8 hours