- Présentation de l'entreprise Le noyau de Shanghai Metal Vision & philosophie Partenariat Certificat Culture d'entreprise

- Nos services Conception et ingénierie Maintenance et entretien Fabricant & Fabrication Mise à jour et transformation Stockage et logistique Traitement et commerce

- Gestion d'entrepise Notre histoire Responsabilité globale

- Centre d'achat Stagiarie

- Produit métallique Produits en aluminium Produits en cuivre Produits revêtus métalliques Produits en acier inoxydable Produits en acier carboné Alliages spéciaux

- Construction & Projet Caillebotis en acier Étagère Structure en acier Pont en acier Système d'échafaudage Matériaux de construction Matériel Chimique One-Stop Solutions pour les Projects

- Conteneur Conteneur standard ISO Conteneur d'équipement Conteneur de stockage Maison conteneur Conteneur frigorifique / isolé Conteneur offshore

- Machine Machine à former des métaux Autres machines Machine à découper les métaux Machine de traitement des métaux Machine à cintrer Machine d'aggloméré

- Produits mécaniques Industrie automobile Divers Équipement d'amarrage Equipment marin Récipient à pression

- Système électromécanique Câble Automation Distribution d'énergie Système d'alimentation solaire Système de protection électrique Convertisseur Ligne de production Système d'éclairage

- Matériel médical Produits de nourriture Produits de voies aériennes Produits de soins infirmiers Produits d'injection

- Machines de construction

- projet epc

- Tuyaux de pétrole

- Tuyaux de l'eau

- Tuyau de gaz

- Bateau et accessoires d'amarrage

- Produit métallique pour la décoration

- Composant du transformateur

- Pipe d'échangeur de chaleur

- Pièces et accessoires de climatisation

- Chaudière

- Appareil de cuisine et de salle de bains

- Métal pour appareils ménagers

- Appareil solaire

- Ascenseur

- Toiture et plafond

- Câble

- Tank

- Emballage

- Pièces détachées et accessoires pour machines et équipements

- Moule

- Pièces d'automobile

- Rail et rail de grue

- Équipement de quincaillerie

- abrasif

- Construction de route

- Composants electroniques

- Matériaux de construction et de décoration

- Portes et fenêtres

- Réfrigérateurs

- News release Nouvelles de l'industrie métallurgique Nouvelles de la machinerie et de l'équipement Nouvelles de la construction et du bâtiment Nouvelles des produits mécaniques Nouvelles de conteneurs Nouvelles du système électrique Nouvelles des matériels médicaux

- Médiathèque Vidéo Image Suivez Shanghai Metal sur les médias sociaux

Tuyau en acier inoxydable soudé

Standard: ASTM A554 / DIN 17455

Outside diameter: 8mm - 1000mm

Wall thickness: 0.3mm - 30mm

Grade: 201, 202, 304, 304L, 316, 316L, 321, 409, 430 etc

Specifications of Welded Stainless Steel Pipe/Tube:

1. Standard:ASTM A554 / DIN 17455

2. Grade: 201, 202, 301, 309, 310S, 321, 304, 304L, 316, 316L, 409, etc

3. OD range: 8mm-1000mm

4. Wall thickness range: 0.3mm-30mm

5. Length: as demand

6. Surface finish: pickling, annealing, manual polish and mechanical polish, mirror polish

7. Manufacture technology: hot rolled, cold drawn

8. Type: Welded

9. Material Quality:

Used For Physical construction : 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb etc.

Used For Fluid transportation : 06Cr19Ni10, 022Cr19Ni10, 06Cr19Ni110Ti, 00Cr17, 0Cr18Ni11Nb, 06Cr17Ni12Mo2 etc.

Features of Welded Stainless Steel Pipe/Tubes:

1. A large stock of pipes ready for call-off

2. Pipes manufactured to specified dimensions on request

3. Pipes can be produced in high quality alloys

4. Pipes can be supplied in a variety of finishes

5. Pipes can be cut to size on our premises ready for immediate supply

6. Worldwide shipping

7. Pipes produced to ISO 9001:2000 quality specification

Production line

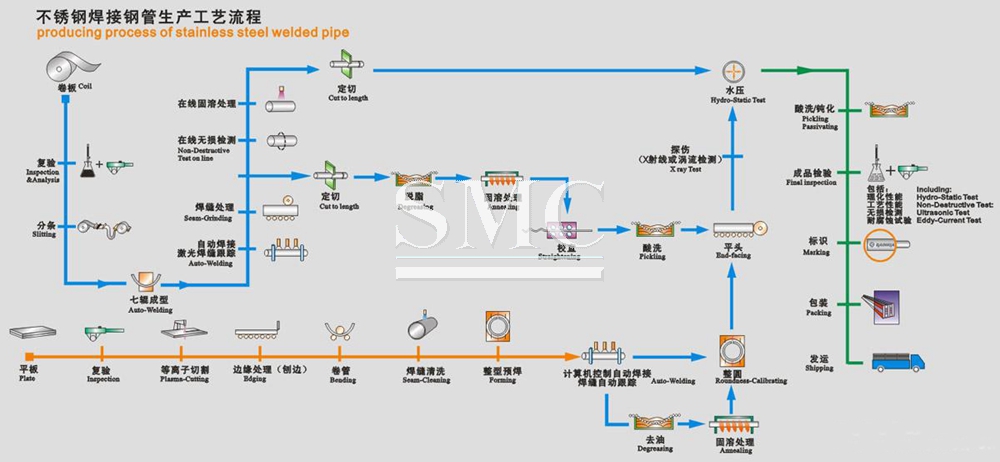

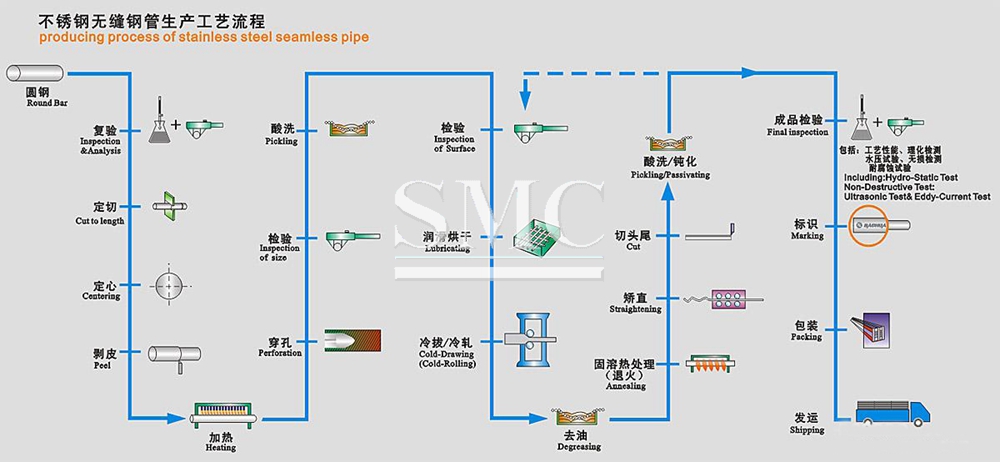

Manufacturing Process of Stainless Steel Pipes/Tubes:

The process commences with the formation of welded mother tube on the tube mill from imported and tested prime quality stainless steel strips. The latest TIG multi electrode welding technique is employed for superior weld quality and 100% Fusion, with argon purging, No filler metal added.

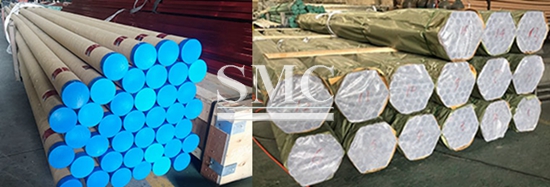

Packaging of Stainless Steel Tubes/Pipes:

All our products are guaranteed to be packed, stored and transported according to the highest international regulations. We care deeply about the quality of our products down to even the smallest detail. We wrap all stainless steel products with anti-rust paper and steel rings to prevent damage. Our storage racks are made of wood and other kinds of metals are placed in other places, far from the stainless steel. Any unwanted chemical reaction can be prevented. Identification labels are tagged according to standard specification or customer's instructions. Special packing is also available as per customer's requirement.

Applications of Welded Stainless Steel Pipes/Tubes:

1. Petroleum, Chemical enterprise, super heater of boiler, heat exchanger

2. High temperature resistant transmission fluid pipe in power station

3. Ship with pressure pipe

4. The exhaust purification device

5. Construction and ornament

FAQ

Q: Can you do polished finish for the tubes/pipes?

A: Yes, for welded tubes/pipes, we can do mirror polishing, 600# polishing, 500# polishing, 320# polishing, 240# polishing and so on, brushed finish is also available. For seamless tubes/pipes, normally the surface is pickled finish, while brushed finish is also doable.

Q: What’s your standard package?

A: Our standard package is waterproof plastic bags with wraps. For advanced packing, we can provide round paper tube for each tube, and wooden/metal case for exterior packing.

Q: Where’s your main market?

A: South America, Mid-east, South-east Asia, Europe and so on.

Q: Do you also have the accessories for the tubes?

A: Yes we can provide the accessories too.

Q: What length is your standard length? Can I have the tubes/pipes cut into the length I want?

A: Our standard length is 3meter, 4meter, 5meter, 6meter. If you length is less than 3meter, we will have to run an additional processing for cutting which will bring some more costs. The minimum length is 500mm. For seamless tubes, we can make maximum to 12, 13meters.

ici

pour

prix

We will contact with you within 8 hours